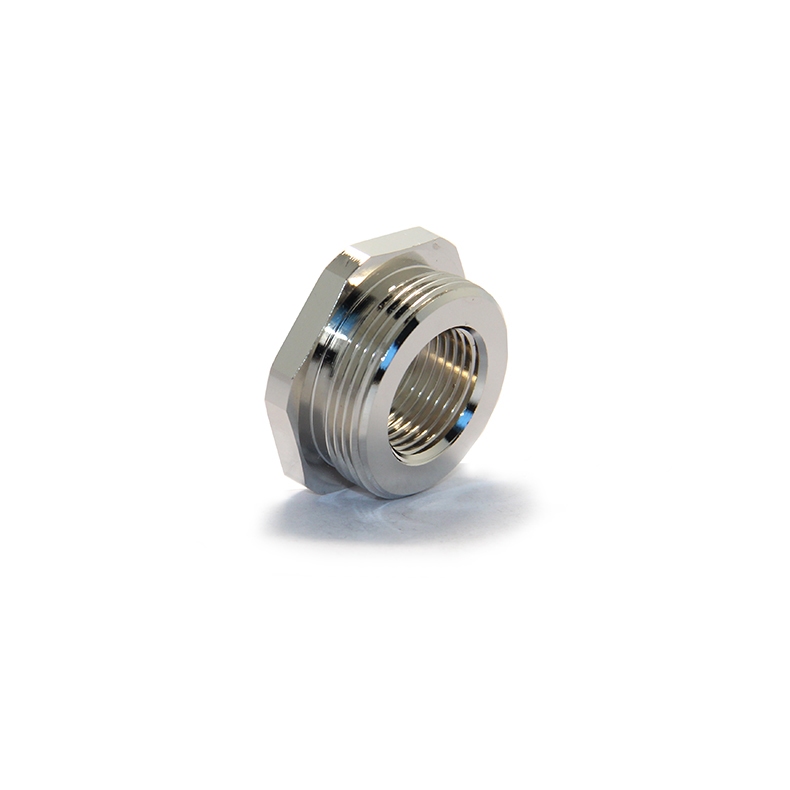

Hex Long Nuts, also known as long hex nuts, hex coupling nuts, or hex extension nuts, are precision fastening components designed to connect two male threads, typically threaded rods or bolts. They provide extended thread engagement and improved stability in mechanical assemblies.

Manufactured with advanced CNC Machining, forging, or cold heading techniques, our metal hex long nuts feature excellent dimensional accuracy, superior tensile strength, and a clean finish.

As a custom hex long nut manufacturer in China, we supply stainless steel, carbon steel, aluminum, and brass hex long nuts in both metric and inch sizes. We also provide OEM/ODM production to meet non-standard or custom requirements for industrial, automotive, and construction applications.

Extended Thread Design: The hex long nut offers greater thread depth for stronger and more secure connections.

High Precision: CNC Machining ensures accurate threads and tight dimensional tolerances.

Versatile Connection: Commonly used as hex coupling nuts or hex spacer nuts to join threaded rods or shafts.

Material Flexibility: Available in stainless steel, carbon steel, aluminum, and brass.

Superior Corrosion Resistance: Options for nickel plating, zinc coating, anodizing, and other finishes.

Custom Manufacturing: Fully custom hex long nuts and non-standard long hex coupling nuts made to drawings or samples.

OEM / ODM Support: Professional metal hex long nut manufacturer in China offering bulk production with stable quality and on-time delivery.

Our hex long nuts are produced through a strict and efficient process that ensures high precision and durability:

Material Selection: Choose from stainless steel, carbon steel, aluminum, brass, or alloy steel.

Cold / Hot Forging: Shape formation under high pressure for maximum density and strength.

CNC Machining & Thread Cutting: Achieve precise internal threading with excellent surface smoothness.

Deburring & Surface Polishing: Remove sharp edges and enhance appearance.

Heat Treatment (Optional): Improve hardness and fatigue resistance.

Surface Finishing: Apply zinc plating, anodizing, or passivation to prevent corrosion.

Quality Inspection: 100% inspection for thread accuracy, dimensional tolerance, and appearance.

We offer a full range of material selections to meet different mechanical and environmental requirements:

Stainless Steel (A2 / A4): Excellent corrosion resistance and aesthetic finish; suitable for marine and outdoor use.

Carbon Steel: High tensile strength and cost efficiency for industrial machinery and general use.

Aluminum: Lightweight and corrosion-resistant, ideal for aerospace and automotive applications.

Brass: Good conductivity and anti-seize properties; commonly used in Electrical and decorative components.

Alloy Steel: Superior strength and hardness for high-load or high-temperature environments.

To enhance performance and lifespan, our hex long nuts can undergo a variety of finishes:

Zinc Plating (Silver / Yellow)

Nickel Plating

Chrome Plating

Anodizing (for Aluminum)

Black Oxide

Passivation

Polishing

We implement a rigorous quality control process under ISO 9001:2015 standards to ensure every hex long nut meets customer expectations.

Thread Tolerance: Up to ±0.01 mm

Surface Roughness: Ra ≤ 0.8 µm

Inspection Equipment: CMM, optical projector, torque tester, hardness tester

Testing Procedures: Thread gauge testing, tensile testing, and surface inspection before shipment

Hex long nuts are widely used across various industries due to their strong joining and alignment capabilities:

Automotive assemblies and chassis structures

Industrial machinery and mechanical systems

Construction and building hardware

Electrical and communication installations

Aerospace and aviation components

Marine and offshore applications

Renewable energy systems (solar panel mounting, wind turbines)

Q1: What is the difference between a hex long nut and a standard hex nut?

A1: A hex long nut is longer, providing greater thread engagement for connecting threaded rods or acting as a coupling nut.

Q2: Can you produce custom hex long nuts?

A2: Yes, we offer custom hex long nuts and non-standard hex coupling nuts based on drawings, samples, or specific mechanical requirements.

Q3: What surface finishes are available?

A3: Common finishes include zinc plating, nickel plating, anodizing, black oxide, and chrome plating, depending on material type and corrosion protection needs.

Q4: What is your production lead time?

A4: Typically 10–20 working days, depending on quantity, specifications, and processing complexity.

Q5: Can I order small batches or prototypes?

A5: Yes, we support small quantity orders for prototype testing before mass production.